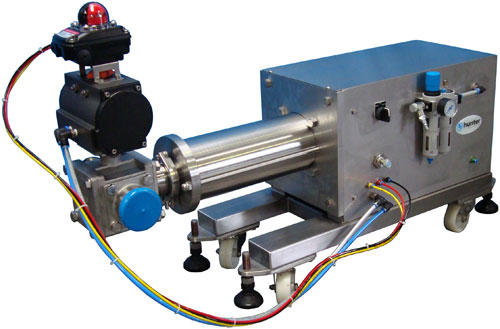

Transfer Pump

The Model 9101 transfer pump is a versatile single head, pneumatically operated volumetric (piston type) dosing unit for product supply of liquid and semi liquid products. Construction is generally corrosion resistant, with frame and covers fabricated in T304 stainless steel. All contact parts are manufactured from T316 stainless steel or suitable plastics, allowing it to be used for such diversified products as foodstuffs and corrosive chemicals.

Fills of 2.50 litres per shot can be achieved using a precision-bored heavy wall metering cylinder - an optional multiple stroke mechanism is available for larger fills. The standard rotary valve has large ports, allowing passage of viscous products – and products containing pieces up to 10mm across, and optionally, an extra large rotary valve may be fitted, enabling the machine to handle pieces up to 20mm across.

The basic transfer pump is pneumatically operated, and is completely safe in a wet (or hazardous) area. It is manufactured to strict hygiene standards, and can be easily disassembled when in-place cleaning is not applicable.

An interfacing mechanism is available to convert the basic semi automatic pump to a fully automatic system suitable for connection with other external devices like hopper level controls.

Products currently being fed by Hunter transfer pumps include dairy & foodstuffs, cosmetics, chemical, automotive, adhesives and paints.